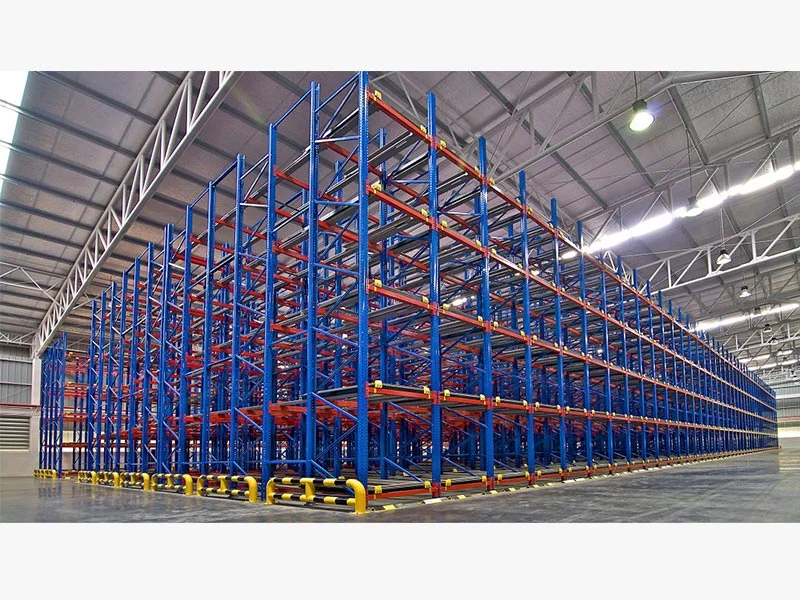

Heavy Duty Pallet Racking System Manufacturer & Supplier in West Bengal: Why Logic Aisle Leads the Way

So, you’re looking for a Heavy Duty Pallet Racking System manufacturer & supplier in West Bengal? You’ve got goods to store, space to maximize, and a business to run efficiently. Let’s be honest, choosing the right racking system isn’t exactly the most glamorous part of the job, but it’s absolutely crucial. A poorly chosen system can lead to inefficiencies, safety hazards, and ultimately, lost money. But don’t worry, we’re here to guide you through it, and we’re going to tell you why Logic Aisle should be at the top of your list.

Why Choose a Heavy Duty System?

First, let’s talk about why you’re even considering a Heavy Duty Pallet Racking System. The clue’s in the name, right? These systems are built to handle serious weight. We’re talking about pallets loaded with heavy materials, bulky goods, and everything in between. If you’re dealing with anything beyond lightweight items, a heavy-duty system is a must. Lighter options simply won’t provide the stability and safety you need.

Think about it: safety is paramount in any warehouse or storage facility. A collapsing rack isn’t just a logistical nightmare; it’s a potential disaster. A robust, well-engineered Heavy Duty Pallet Racking System minimizes that risk, protecting your employees, your products, and your business.

Logic Aisle: Your Trusted Partner in West Bengal

Okay, so you need a heavy-duty system. Now, who do you trust to provide it? That’s where Logic Aisle comes in. We’re not just another manufacturer and supplier; we’re your partners in optimizing your storage space. Based in West Bengal, we understand the local market, the challenges businesses face, and the specific requirements for racking systems in this region. We pride ourselves on delivering high-quality, durable, and custom-designed solutions that meet your exact needs.

What Makes Logic Aisle Different? Our USP

Every company claims to be the best, but what truly sets Logic Aisle apart? Here’s a peek at our unique selling propositions (USPs):

- Customization is Key: We don’t believe in a one-size-fits-all approach. We work closely with you to understand your specific storage needs, the dimensions of your warehouse, and the types of goods you’re storing. This allows us to design a Heavy Duty Pallet Racking System that’s perfectly tailored to your operation.

- Uncompromising Quality: We use only the highest-grade materials and employ rigorous quality control measures throughout the manufacturing process. This ensures that our racking systems are built to last, even under the most demanding conditions.

- Expert Installation: A great racking system is only as good as its installation. Our experienced team of installers ensures that your system is properly assembled and secured, guaranteeing its stability and safety.

- Competitive Pricing: We understand that cost is a factor. We strive to offer competitive pricing without compromising on quality or service. We believe in providing value for your investment.

- Dedicated Support: Our commitment doesn’t end with the sale. We provide ongoing support and maintenance services to ensure that your racking system continues to perform optimally for years to come.

Benefits of Choosing Logic Aisle’s Heavy Duty Pallet Racking System

Let’s break down the tangible benefits you’ll experience when you choose Logic Aisle as your Heavy Duty Pallet Racking System manufacturer & supplier in West Bengal:

- Increased Storage Capacity: Our systems are designed to maximize your available space, allowing you to store more goods in the same footprint. This is especially valuable in areas where real estate is at a premium.

- Improved Warehouse Efficiency: A well-organized racking system streamlines your warehouse operations, making it easier to locate and retrieve goods. This translates to faster order fulfillment and reduced labor costs.

- Enhanced Safety: Our robust designs and expert installations minimize the risk of accidents and injuries, creating a safer working environment for your employees.

- Reduced Product Damage: Proper racking prevents goods from being crushed or damaged, reducing losses due to spoilage or breakage.

- Long-Term Cost Savings: While the initial investment in a heavy-duty system may be higher than a lighter option, the long-term cost savings from increased efficiency, reduced damage, and improved safety make it a worthwhile investment.

- Scalability: Our systems are designed to be scalable, meaning you can easily add or reconfigure them as your business grows and your storage needs evolve.

Understanding Different Types of Heavy Duty Pallet Racking Systems

While we customize each system, there are some common types of Heavy Duty Pallet Racking System that you should be aware of:

- Selective Pallet Racking: This is the most common type, offering direct access to every pallet. It’s ideal for warehouses with a wide variety of SKUs.

- Drive-In/Drive-Thru Racking: This system is designed for high-density storage of similar goods. Forklifts drive into the racking to load and unload pallets.

- Push-Back Racking: This system uses a series of carts to store pallets, allowing for deep lane storage and first-in, last-out (FILO) inventory management.

- Pallet Flow Racking: This system uses gravity to move pallets along inclined rollers, providing first-in, first-out (FIFO) inventory management.

- Cantilever Racking: This system is designed for storing long, bulky items such as lumber, pipes, and furniture.

We can help you determine which type of racking system is best suited to your specific needs and operational requirements.

Factors to Consider When Choosing a Heavy Duty Pallet Racking System

Before you make a decision, here are some key factors to consider:

- Weight Capacity: Ensure that the racking system is designed to handle the maximum weight of your pallets.

- Warehouse Dimensions: Carefully measure your warehouse space to determine the optimal layout for your racking system.

- Forklift Compatibility: Ensure that your forklifts are compatible with the racking system you choose.

- Inventory Management: Consider your inventory management needs (FIFO or FILO) when selecting a racking system.

- Safety Standards: Ensure that the racking system meets all relevant safety standards and regulations.

Working with Logic Aisle: The Process

So, what’s it like to work with Logic Aisle? Here’s a brief overview of our process:

- Initial Consultation: We start with a detailed consultation to understand your needs and requirements.

- Site Assessment: We conduct a thorough site assessment to evaluate your warehouse space and operational environment.

- Design and Engineering: Our team of experienced engineers designs a custom racking system that meets your specific needs.

- Manufacturing: We manufacture your racking system using high-quality materials and rigorous quality control measures.

- Installation: Our experienced installers ensure that your racking system is properly assembled and secured.

- Ongoing Support: We provide ongoing support and maintenance services to ensure that your racking system continues to perform optimally.

Frequently Asked Questions (FAQs)

Here are some common questions we receive about our Heavy Duty Pallet Racking System:

- Q: What is the lead time for a custom racking system?

- A: Lead times vary depending on the complexity of the project, but we strive to deliver your system as quickly as possible. We’ll provide you with a realistic timeline during the initial consultation.

- Q: Do you offer financing options?

- A: We can discuss financing options to help you manage the cost of your racking system.

- Q: What type of warranty do you offer?

- A: We offer a comprehensive warranty on our racking systems to protect you against defects in materials and workmanship.

- Q: Can you help us with warehouse layout design?

- A: Yes, our team can assist you with warehouse layout design to optimize your space and improve efficiency.

- Q: Do you provide maintenance services?

- A: Yes, we offer ongoing maintenance services to ensure that your racking system continues to perform optimally.

- Q: What is the cost of